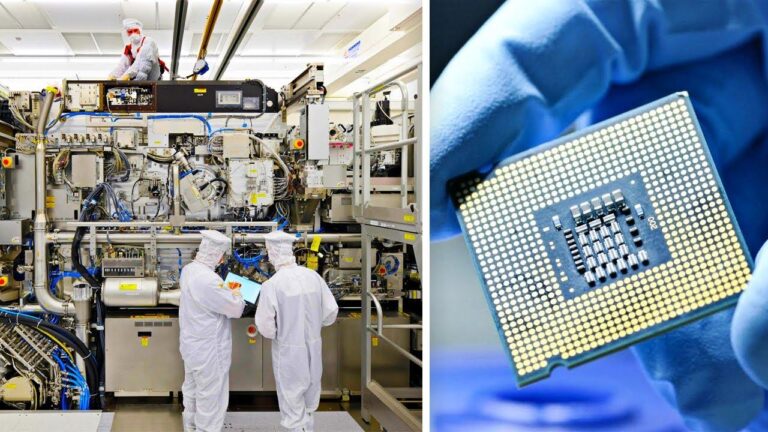

Taiwan Semiconductor Manufacturing Company (TSMC), the world’s leading contract chipmaker, is set to receive $6.6 billion in funding to expand its manufacturing presence in the United States, according to a report published by The New York Times in 2024. This significant investment is part of broader efforts to strengthen U.S. semiconductor production amid growing geopolitical tensions and supply chain vulnerabilities. The move underscores the critical role of chip technology in national security and economic competitiveness, marking a pivotal moment in the global semiconductor landscape.

TSMC Partnership Marks Major Boost for U.S. Semiconductor Industry

The infusion of $6.6 billion into TSMC’s U.S. operations represents a significant advancement for the country’s semiconductor landscape, aimed at reducing dependency on foreign chip supplies. This massive investment will enable TSMC to expand its manufacturing footprint in Arizona, create thousands of skilled jobs, and accelerate research and development of next-generation chip technologies domestically.

Key benefits of this partnership include:

- Strengthened supply chains to safeguard against global disruptions

- Boosted innovation through collaboration with U.S. tech and research institutions

- Economic growth driven by high-tech manufacturing and employment opportunities

| Project Element | Details |

|---|---|

| Investment Amount | $6.6 Billion |

| Location | Arizona |

| Jobs Created | Approx. 4,000 |

| Focus | Advanced Chip Manufacturing |

Strategic Investments Set to Enhance Domestic Chip Production Capacity

In a decisive move to fortify the United States’ semiconductor supply chain, TSMC is set to receive a substantial investment package totaling $6.6 billion. This funding, part of a broader initiative to reduce reliance on foreign chip manufacturing, will accelerate the development of cutting-edge fabrication facilities on American soil. The goal is clear: to expand domestic production capacity and enhance technological competitiveness in the global market.

The investment will focus on several key areas:

- Construction of advanced fabs: New plants equipped with state-of-the-art production lines designed to manufacture chips at the most advanced nodes.

- Research and development: Dedicated resources to innovate process technology, aiming for higher efficiency and performance.

- Workforce expansion: Recruitment and training initiatives to build a skilled talent pool capable of supporting complex semiconductor manufacturing operations.

| Investment Area | Focus | Expected Outcome |

|---|---|---|

| Facility Expansion | New fabs and infrastructure | Increased chip output |

| Process Innovation | Advanced R&D programs | Competitive technology edge |

| Talent Development | Hiring and training | Skilled domestic workforce |

Implications for Global Supply Chains and Technology Competitiveness

The substantial investment in TSMC’s U.S. manufacturing capabilities marks a significant shift in the global semiconductor landscape. By localizing advanced chip production, the U.S. aims to reduce reliance on East Asian supply chains, which have been vulnerable to geopolitical tensions and pandemic-related disruptions. This move is expected to foster a more resilient technology ecosystem that can better withstand international trade uncertainties and supply shocks. Moreover, the presence of a major player like TSMC on American soil will likely attract ancillary businesses and innovation hubs, catalyzing a robust tech manufacturing corridor.

From a competitiveness standpoint, this funding injection acts as a crucial countermeasure in the ongoing technology race. Countries around the world are fiercely competing to own the next generation of semiconductor technology, and securing leadership in chip manufacturing is integral to maintaining national security and economic dominance. Key implications include:

- Enhanced R&D capabilities: Driving innovation in chip design and fabrication processes.

- Talent retention and growth: Creating high-skilled jobs and attracting specialized engineers.

- Strategic autonomy: Reducing dependency on foreign technology and supply interruptions.

| Factor | Expected Impact |

|---|---|

| Supply Chain Diversification | Improved resilience and shorter lead times |

| Technology Advancements | Faster innovation cycles, leading in 3nm+ chips |

| Economic Growth | Boost in manufacturing jobs and local economies |

Policy Recommendations to Maximize Impact of Federal Funding on Innovation

To ensure that federal investments, such as the $6.6 billion allocated to TSMC, translate into lasting advancements, policymakers must adopt a multifaceted approach. First and foremost, increased transparency and accountability in fund distribution are essential. This could be achieved by instituting a robust oversight framework that periodically assesses project milestones and innovation outputs. Moreover, fostering collaboration between private industry leaders, academic institutions, and government agencies will accelerate technology transfer and elevate the U.S.’s competitive edge in semiconductor manufacturing.

Equally important is the emphasis on workforce development and regional innovation ecosystems. Federal grants should be tied to initiatives that strengthen local talent pipelines, including upskilling programs and STEM education incentives. Additionally, fostering diversity in tech sectors will unleash untapped creativity and resilience. Key policy priorities include:

- Implementing outcome-based funding tied to measurable innovation benchmarks

- Promoting regional hubs to decentralize manufacturing and stimulate disadvantaged communities

- Encouraging public-private partnerships that integrate research with commercial feasibility

- Investing in cutting-edge R&D that anticipates future market needs

| Policy Focus | Expected Impact | Implementation Timeline |

|---|---|---|

| Outcome-Based Funding | Increased innovation efficiency | 1-2 years |

| Regional Innovation Hubs | Economic diversification | 3-5 years |

| Workforce Development | Talent retention and growth | Ongoing |

Concluding Remarks

As TSMC secures a $6.6 billion investment to expand its U.S. chip manufacturing capabilities, the move marks a significant milestone in the broader effort to strengthen domestic semiconductor production. This funding aligns with national priorities to reduce reliance on foreign supply chains and bolster technological competitiveness. The coming years will be critical as TSMC and other key players ramp up operations, shaping the future landscape of the global chip industry.