A groundbreaking startup is pioneering a sustainable solution to America’s critical metal shortage by transforming mining waste into valuable resources. Highlighted recently by MIT News, this innovative approach not only addresses the growing demand for essential metals used in advanced technologies but also offers a promising path to reduce environmental impact. As the U.S. seeks to secure its supply chains and promote green initiatives, this development marks a significant step forward in the intersection of technology, sustainability, and national resource resilience.

Startup Innovates to Extract Rare Metals from Mining Waste Boosting U.S. Supply Chain

In a breakthrough that promises to reshape the landscape of critical metals sourcing, a Boston-based startup has unveiled a pioneering technique that transforms discarded mining residues into a rich source of rare metals. These metals—essential for national security and the production of advanced electronics—have long faced supply chain vulnerabilities, making domestic extraction imperative. By leveraging cutting-edge chemical processing, the company is able to recover metals such as lithium, cobalt, and rare earth elements from tailings that were previously considered worthless. This innovation not only addresses environmental concerns but also strengthens the U.S. position in the global race for resource independence.

- Environmental Impact: The startup significantly reduces hazardous waste and mitigates pollution from mining operations.

- Economic Value: Generates new revenue streams by converting low-value waste into high-demand materials.

- Supply Chain Resilience: Decreases reliance on imported metals amidst geopolitical uncertainties.

| Metal | Recovery Rate | Primary Use |

|---|---|---|

| Lithium | 85% | Battery Manufacturing |

| Cobalt | 78% | Electronics & Aerospace |

| Rare Earth Elements | 65% | Magnets & Defense Tech |

Advanced Technology Enables Efficient Recovery of Critical Minerals from Scrap Materials

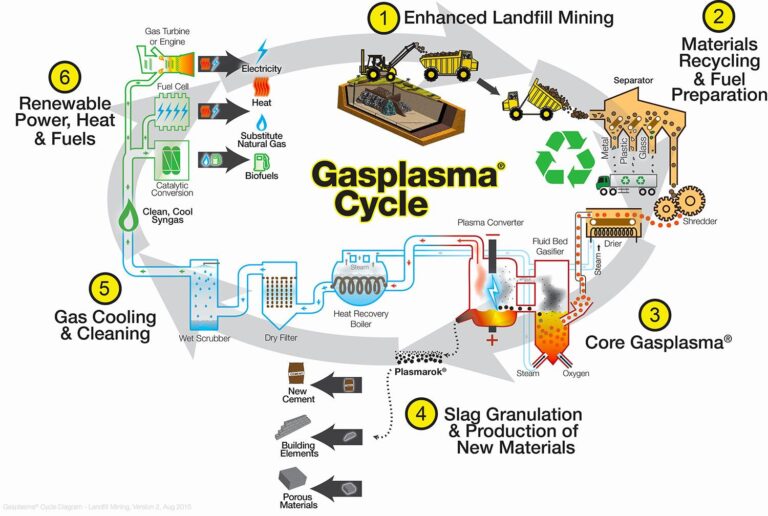

By harnessing cutting-edge hydrometallurgical methods, the startup has developed a proprietary process that extracts essential critical minerals such as lithium, cobalt, and rare earth elements from electronic waste and mining residues. This approach dramatically reduces the environmental footprint compared to traditional mining, which often involves energy-intensive extraction and significant landscape disruption. The integration of AI-driven sorting and separation technologies further enhances recovery efficiency, ensuring that even low-grade scrap materials are processed with minimal waste.

Key innovations driving this technology include:

- Selective leaching techniques tailored for complex metal mixtures

- Real-time monitoring systems optimizing chemical reagent usage

- Advanced material characterization ensuring maximum purity levels

| Mineral | Recovery Rate | Source Material |

|---|---|---|

| Lithium | 92% | Spent batteries |

| Cobalt | 88% | Electronic scrap |

| Neodymium | 85% | Magnet waste |

Environmental Impact Reduced Through Sustainable Recycling Practices in Metal Extraction

By transforming mining waste into valuable metals, the startup has introduced a groundbreaking approach that significantly cuts the environmental toll traditionally associated with metal extraction. This innovative process reduces landfill waste and minimizes the need for environmentally destructive mining operations, preserving natural landscapes and biodiversity. Utilizing advanced recycling technologies, the initiative not only conserves critical resources but also reduces greenhouse gas emissions by limiting energy-intensive ore processing.

Key sustainable practices highlighted include:

- Closed-loop recycling circuits to prevent toxic runoff

- Energy-efficient separation techniques that lower carbon footprints

- Use of renewable energy within extraction facilities

| Impact Metric | Traditional Mining | This Startup’s Approach |

|---|---|---|

| Carbon Emissions | High | Reduced by 60% |

| Waste Generated | Extensive tailings | Minimal solid waste |

| Energy Use | Intensive | Energy-efficient processes |

Experts Recommend Expanding Support for Circular Economy Initiatives in Mining Sector

Industry leaders emphasize the urgent need to build robust frameworks supporting circular economy models within mining operations. Experts point out that leveraging waste as a resource not only conserves natural reserves but also strengthens the supply chains for critical metals essential in high-tech and clean energy applications. Governments and private stakeholders are urged to collaborate on incentivizing innovation that transforms mining byproducts into valuable materials, reducing environmental impact and promoting economic resilience.

Highlighted by recent breakthroughs, initiatives like the MIT-affiliated startup demonstrate tangible benefits from scaling circular solutions. Below is an overview of key recommendations from industry specialists:

- Increased funding: Direct federal and state grants towards startups and research projects focused on metal recovery technologies.

- Policy reforms: Streamline regulatory approvals to facilitate implementation of recycling processes in active mines.

- Public-private partnerships: Foster collaborations to share knowledge, infrastructure, and investment risks effectively.

- Education and training: Develop workforce skills tailored to sustainable practices in mineral extraction and recycling.

| Support Area | Impact | Example |

|---|---|---|

| Research Grants | Accelerates innovation | Recovery tech startups |

| Regulatory Incentives | Reduces barriers | Expedited permits |

| Collaborative Ventures | Shares resources | Mining consortiums |

| Workforce Development | Builds expertise | Specialized training |

Future Outlook

As the demand for critical metals continues to surge amid a global push for clean energy and advanced technologies, innovative solutions like this startup’s approach to repurposing mining waste offer a promising pathway toward sustainable resource management. By transforming discarded materials into valuable commodities, the company not only addresses supply chain vulnerabilities but also sets a precedent for circular economy practices in the mining sector. With backing from leading institutions such as MIT, this initiative exemplifies how cutting-edge research and entrepreneurship can converge to meet national strategic needs while fostering environmental stewardship.